|

|

| |

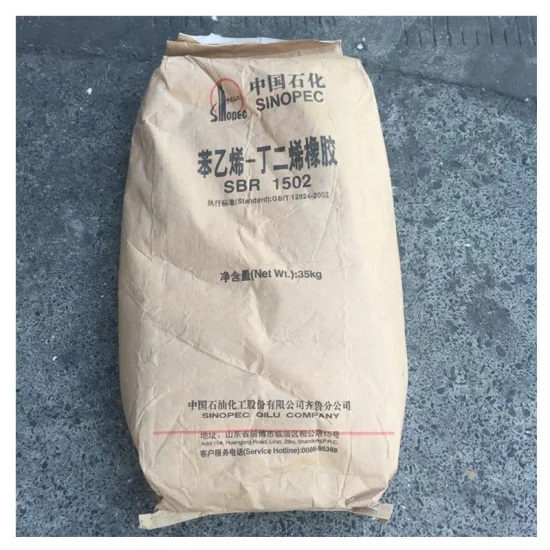

Styrene Butadiene Rubber / SBR1502

SBR 1502 is one of the most widely used synthetic rubber.

Low temperature emulsion polymerized technique. Its wear resistance,aging resistance,ozone resistance,water-proofing,air tightness and homogenous are much better.

|

testing Item

|

Value

|

Test Method

|

|

Volatile matter(%)

|

0.75-0.90

|

GB/T6737

|

|

Ash content

|

°‹0.50

|

GB/T4498A

|

|

Organic acid(%)

|

4.50~6.75

|

GB/T8657A

|

|

Soap content(%)

|

°‹0.5

|

|

Combinated Styrene content(%)

|

22.5~24.5

|

GB/T8658

|

|

Raw rubber mooney viscosity

ML(1+4)100ºC

|

44~55

|

GB/T1232.1

|

|

Compounded rubber mooney viscosity

ML(1+4)100ºC°‹

|

93

|

|

300% Stretching Stress

(145ºC)/MPa

|

25min

|

14.7~19.6

|

GB/T8656A

|

|

35min

|

20.6°ņ2.5

|

|

50min

|

21.5°ņ2.5

|

|

Tensile strength (145ºC, 35min)/MPa

|

°›24.5

|

|

Elongationg at break (145ºC, 35min)/%

|

°›330

|

|

Heat Distortion Temperature,@0.45MPa(66 psi)

|

ºC

|

ASTM D648

|

77

|

|

Haze

|

%

|

|

< 1.0

|

|

Transmittance

|

%

|

ASDM D541

|

91

|

|

Refractive Index

|

|

ASDM D542

|

1.56

|

End Use:

End uses include white sidewall tires, footwear, light and dark coloured mechanical goods and miscellaneous items where excellent physical properties and minimum discoloration and staining are required.

Packing:35 kg / bag

|

| |

|